Products Details

Our cup sealing film is available in various thicknesses and sealing layers for a wide range of applications. Benefits include a common barrier to oxygen and water vapor transmission and more flexibility in the sealing process. In flexible packaging, Aluminum is used widely as a complete heat and moisture barrier.

Our cup sealing film are available with a heal lacquer or co-extruded sealing layer to suit a wide range of substrates. Benefits include high puncture and tear resistance, high quality print and the ability to metal detect.

There are two types of lid film: common and easy to tear. Easy to tear lid film is translucent, flexible, thermoplastic, high-performance waterproof material, its own colorless, odorless, tasteless.

The unique properties of rip-off lid film make it ideal for many important laboratory and technical applications. It is tightly and automatically sealed to form on test tubes, flares, a variety of irregular tools and surfaces. Its high low sensitivity to moisture vapor, moisture loss, moisture absorption, and permeable gases makes it an ideal covering tool for mobile pools.

Features

• Easy to peel with out shredding.

• Maintain a tight seal to extend shelf life.

• Protecting products and preventing leaks with reliable hermetic seals.

• Providing consumers with consistent peeling, with the specified seal strength range.

• Creating more efficient package lines with fewer hang-ups and rejects.

• Shape, print and size is flexibly customized to fit the cup.

Application

While the market is keeping changing, packaging which generates first impression to consumers, is required to be more flexible and innovated. Customized cups and lids have becoming the platform for brands to show their culture and equity. Applied by products like Salads, fresh cuts, yogurt, soups, frozen foods, or any refrigerated foods & other foods, such as popcorn, candies, all kinds of packaging for food and pharmaceutical products.

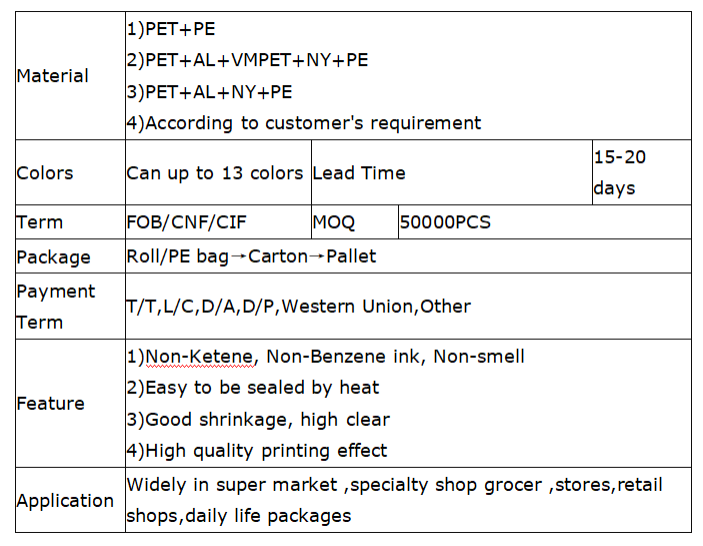

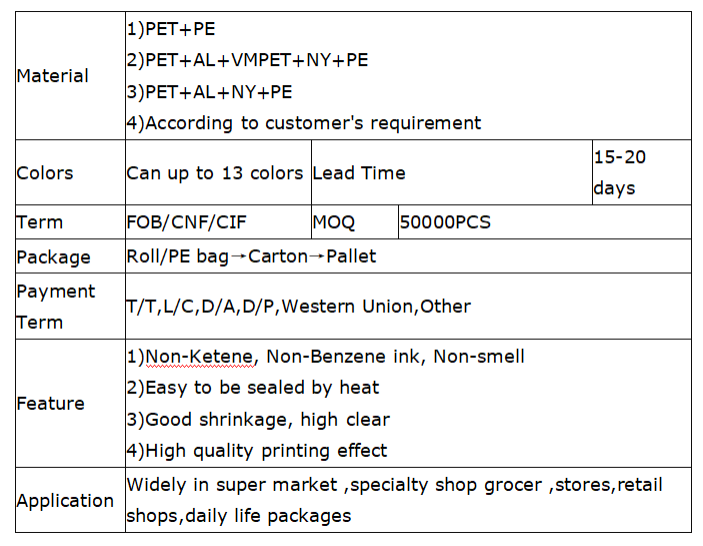

Product Parameter

Related Product

Packaging & Shipping

Previous:

Snack Packaging film Packaging Plastic Roll Film Automatic Packaging Film

Next:

Cat Food side gusset bag Large Capacity Mylar Bag Shock Resistant Side Gusset Pouch

.jpg)

.jpg)

1.jpg)